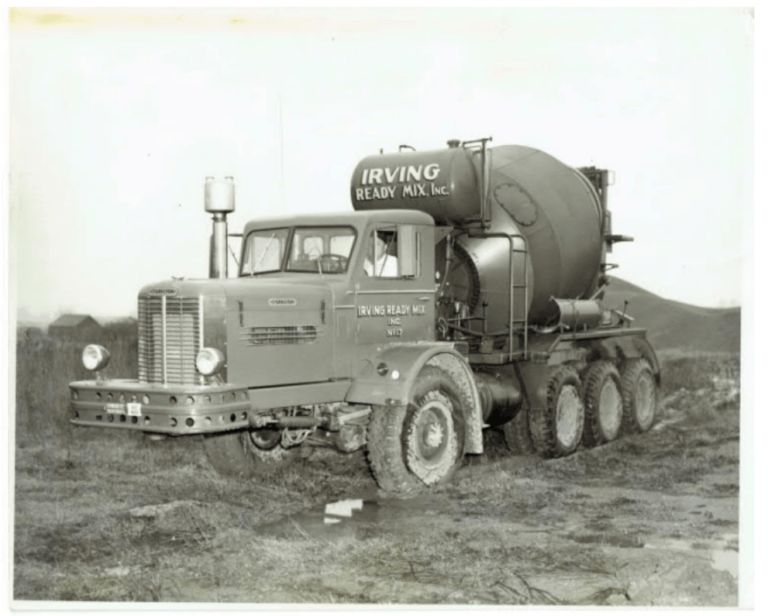

Company History

The earliest family-owned division of imi was founded in 1928 as Irving Brothers Gravel Company. Nearly a century later, Irving Materials, Inc. is now a leading supplier and producer of aggregates, ready-mix concrete, and asphalt. The company’s construction divisions, E&B Paving and Specialties Company, specialize in site development, heavy highway, and civil construction.

Customers don’t care how long you’ve been in business. They care about what you can do for them now.

Trusted for safely delivering high-quality custom work.

Our 5 Fundamentals: Safety, Quality, Custom Solutions, Sustainability & Long-Term Relationships

Safety

From the office to the job site and every roadway in between, there’s nothing more important than everyone returning home safely.

Quality

Quality is an outcome only achieved by investing in the right people, materials, training, technology, and equipment. imi consistently delivers superior quality on every project.

Custom Solutions

Throughout all divisions of imi, we customize a solution for every job. We create customer-specific ready mix concrete, asphalt mix designs, and soil-stabilization services.

Sustainability

imi proactively works to lower our embodied carbon footprint. We were early adopters of solutions like CarbonCure and choose materials that reduce transport and waste.

Long-Term Relationships

For nearly 100 years, imi has focused on building long-term relationships with customers and industry partners. By providing expertise and delivering high-quality custom work, our relationships have stood the test of time.

Employees are our greatest asset

We build more than bridges, buildings, and roads. We build leaders, teams, and communities. Apply today to build your bright future with imi.